Views: 0 Author: Site Editor Publish Time: 2026-01-04 Origin: Site

Table of Content

Why Fresh Fruit Producers Are Shifting to Automation

Types of Packing Automation Systems

How Automation is Transforming Agricultural Production

What to Consider When Buying a Packing Automation Machine

How to Manage the Challenges of Packing Automation Systems

Conclusion

Production agriculture is rapidly evolving as smart technologies reshape how food is packaged, shipped, and delivered around the country and even the world. In this article, you’ll learn how packing automation plays a role in improving efficiency, product safety, and scalability to help modern businesses meet deadlines.

Packing automation refers to the use of automated machinery to handle, pack, seal, and prepare agricultural products for storage, transport, or sale with minimal human intervention. These integrated systems replace manual tasks such as filling, weighing, sealing, and palletizing.

Packing automation is applied to products like fruits, vegetables, grains, and other processed products to reduce product damage, improve hygiene, and maintain steady output.

Fresh fruit producers and retailers demand packaging that is consistent and hygienic. Thus, they are shifting towards automation to deliver certain requirements. Here’s why they are moving towards it:

Address labor issues: The agricultural industry heavily depends on manual labor, leading to a rise in minimum wage and a drop in the workforce. Packing automation provides a secure alternative to performing manual tasks.

Increased Efficiency: Manual fruit packaging is slow. On the other hand, automated packing improves packing speed, delivering consistency at scale, ensuring that every fruit packed meets the same quality requirements.

Enhanced Product Quality: Machine integration ensures consistent sealing of products, thus extending their shelf life and reducing bruising and product damage.

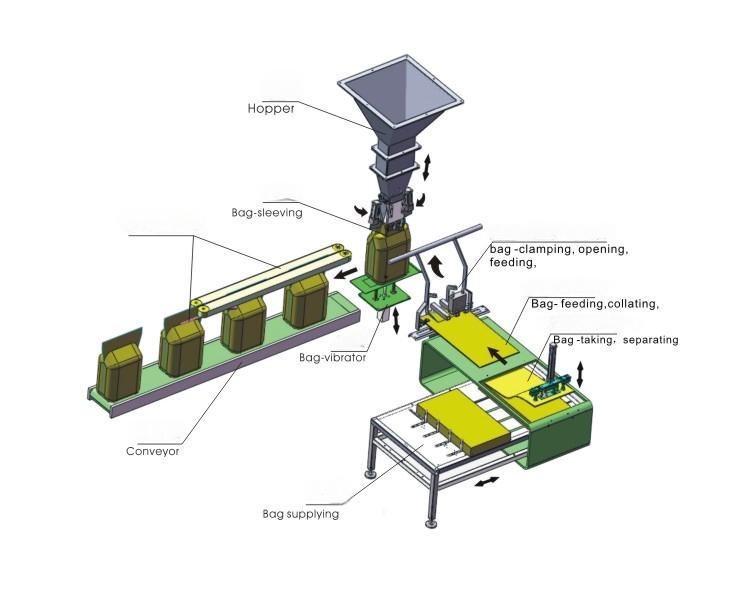

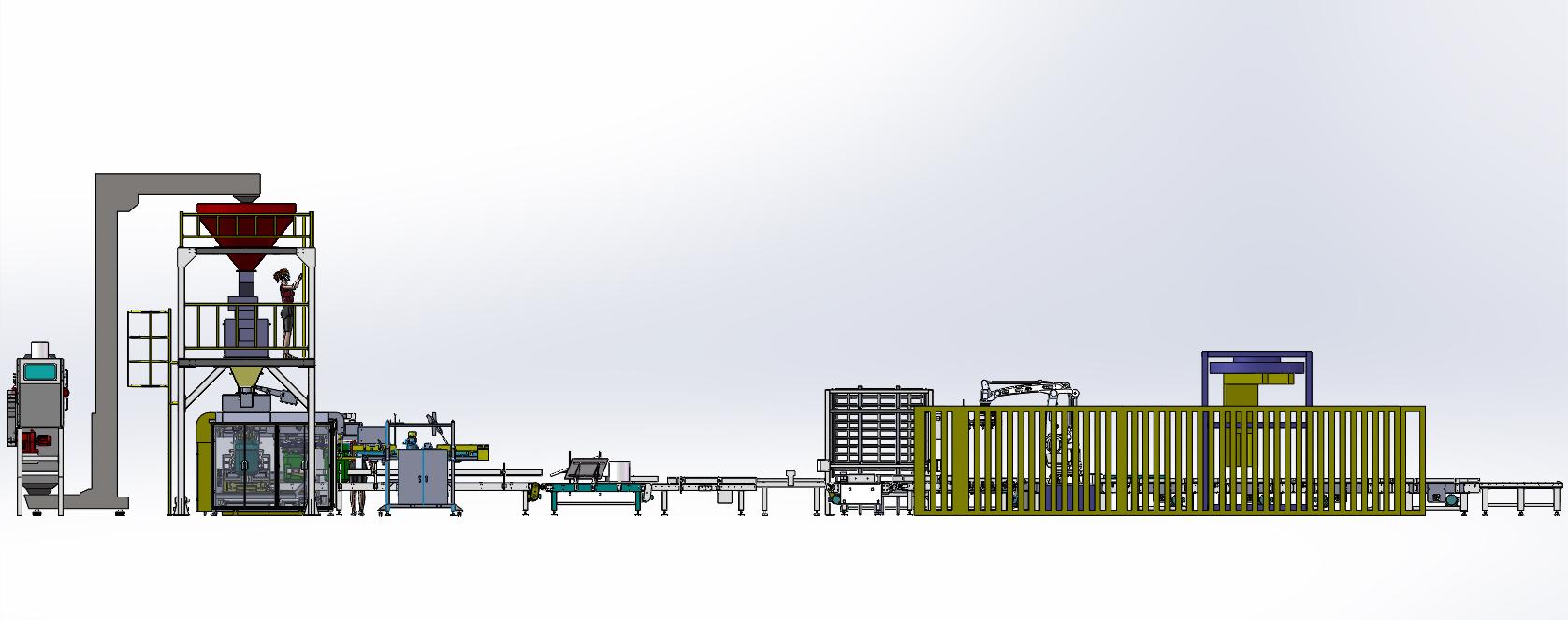

Bagging packaging machine: It is used to package granular and powdery materials into mesh or paper bags with accurate weight control. and can handle bags weighing 10-50kg. Bagging machines improve packing speed, reduce product giveaway, and create uniform bags that are suitable for local and global export markets.

Automated carton erectors: They are used to prepare agricultural products for loading with the help of corrugated cartons. They are typically used at the beginning of the packaging lines where a high volume of boxes is needed. Furthermore, they are used to package fresh fruits like oranges, grapes, and apples. Fresh vegetables like tomatoes, peppers, and cucumbers.

Robotic case packing and sealers: They automatically place finished retail packs into cartons and seal them using tape or glue. These systems are designed to handle repetitive tasks with high precision while minimizing product handling. used to package pre-packed fresh fruits and vegetables like leafy greens.

Robotic palletizers: These automated systems stack sealed cartons onto pallets in stable patterns for storage, cold-chain handling, or shipping. They are usually integrated at the end of the packaging lines before they are stored and distributed. In addition, they are used to package boxed fresh fruits like apples, pears, citrus, and table grapes. Boxed vegetables like potatoes, onions, carrots, cabbage, tomatoes, peppers, and cucumbers.

Examples of Bag Filling Machines

For producers who need faster, more consistent bulk bagging, Hualian’s ZSG-1000G series offers a fully automatic, high-speed solution for grain, feed, and food applications. It’s designed to keep output stable while reducing manual handling—especially when you’re running multiple bag sizes or switching products often. Key highlights include:

Fast, reliable bag feeding with strong adaptability across different bag sizes and formats.

Automatic bag presence/detection to help avoid mis-filling when the bag isn’t properly positioned; weighing accuracy up to ±0.2%.

A streamlined workflow that can cover bag loading → filling → conveying → sealing in one continuous process.

Easy to integrate with an automatic sealing unit and palletizing to build a more complete, fully automated packaging line.

User-friendly control and programming, supporting code-assisted or graphical instruction setup to reduce operator interruption.

Quick changeover capability, so different bag specifications can be swapped in a short time.

Suitable for a wide range of industries, including chemical materials, pharmaceutical raw materials, grains, feed, and food.

Packing automation integrates gentle handling technologies designed to protect sensitive and fragile fresh produce, like berries, tomatoes, grapes, peaches, and apples. These fruits areprone to bruising, crushing, and surface damage when not handled properly. Automated systems minimize human contact by using engineered conveyors, soft-drop mechanisms, and servo-driven movements. These systems move products smoothly and minimize vibration.

Automated systems help maintain the natural appearance and texture of fresh produce. This is important in delicate fruits designed for export markets. This also means fewer rejection rates, reduced waste, and longer shelf life.

Manual handling of products often poses error risks in filling, weighing, and measurement. Automation fixes this with a high level of accuracy, from weighing to filing and portioning. Automated systems, like multi-head weighers and integrated checkweighers, ensure every pack meets exact weight specifications without inconsistencies.

With precision weight control, fresh produce like fruits, vegetables, grains, and nuts regulate retail packs across large production volumes. The accurate weighing reduces product giveaway, allowing farm producers to optimize yield and efficiently manage costs.

Food safety and hygiene are top concerns in agricultural products. Retailers and consumers are seeking products that are fresh, safe, and healthy, and automation perfectly fits in packing facilities. Stainless steel machines with grades 304 and 316 are readily available for high-moisture fruits that are susceptible to mold and bacterial growth. These machines have smooth surfaces and food-grade components that are easy to clean and corrosion-resistant.

Their clean design reduces contamination compared to manual packing areas, where frequent human touch increases the presence of microorganisms. Packing machines feature automated sealing, bagging, and case packing to create enclosed processes that protect agricultural produce from external contaminants.

By packaging lettuce, tomatoes, bell peppers, pears, and apples, they improve hygiene and reduce the risk of recalls.

Packing automation uses modern packing technologies to extend the shelf life of fruits and veggies. One of such technologies is the Modified Atmosphere Packaging (MAP), where controlled sealing temperatures help to slow down oxidation, moisture loss, and microbial growth. MAP is used to package fresh fruits, like berries and grapes, vegetables, cut produce, etc.

Packing automation also uses a vacuum or skin packaging to provide a tamper-proof seal for cut fruits. These methods ensure consistent sealing quality and maintain freshness during transportation, storage, and display. Furthermore, it reduces food waste and enhances visual appeal without compromising product quality.

Packing automation increases speed compared to manual handling. During peak harvest seasons, manual handling slows down production. As a result, agricultural produce will not be able to meet deadlines. Automated systems, like automated bagging, sealing, case packing, and palletizing systems, operate at high speeds, allowing producers to meet deadlines and handle large volumes without gridlock.

High packing speed reduces delays, which can affect freshness and quality. Packing automation also allows businesses to operate with few workers, which reduces labor costs, maintains consistent output, and reduces reliance on manual labor.

The export market has strict requirements on packaging quality, labeling accuracy, and hygiene of agricultural produce. This is because these products are high-moisture and fragile. With packing automation, agricultural producers meet export standards by having uniform pack sizes, secure seals, accurate labeling, and stable packaging for long-distance transport.

Automated systems, like robotic case packing and palletizing systems, regulate the sizes of cartons and pallets, ensuring they meet international standards. This reduces product damage during transportation, helping it retain its shape and profile. Automation also supports traceability and brand confidence, helping build sustainable relationships with others in the business field.

Consider your packaging goals: Packing facilities may have different objectives, from improving the shelf-life of products to reducing labor costs or increasing daily output. Some producers focus on retail packs, like bags or trays. Others focus on bulk cartons for wholesale distribution. Still, others opt for export trays and premium gift boxes. Understanding your packaging goal will help you know the best packaging technology to employ.

Evaluate your production volume: Consider your production volume so you can purchase a valuable and cost-effective machine. Small-scale volume may not need a full automation machine. Since they have limited daily output, they may benefit from semi-automatic bagging or sealing machines. Medium to large-scale volume needs automation to meet deadlines. Understanding your production volume will prevent gridlock and save significant costs. It will also ensure better return on investment.

Match machine type with fruit characteristics: Different agricultural products need different handling and packaging technologies. Match machine type with fruit texture and fragility. Soft fruits, like berries, tomatoes, and peaches, need gentle handling systems to avoid bruising and product damage. Firm fruits like apples can handle robust packing methods like robotic case packing. Size is also important. Machines must align with the fruit size to ensure accurate packing and sealing.

Evaluate machine features: Evaluate machine key features and how it affects efficiency and reliability. Look for machines with adjustable speed controls, accurate weighting systems, stable sealing performance, soft touch interface, and compatibility with different packaging materials. Since it will be used in agricultural environments, choose stainless steel machines with easy-clean designs and energy-efficient options. Well-designed machines reduce maintenance issues and improve uptime.

Evaluate warranty and suppliers’ after-sales support: Automation is a long-term investment, so choose a supplier that will give you ongoing support even after purchase. Reliable suppliers should offer long-term support, including clear warranties, spare parts, technical documentation, and advice. After-sales support reduces downtime and protect production line, ensuring your machine remains efficient, reliable, and profitable.

While packing automation is transforming modern agriculture, there are several challenges that are often encountered. Here are some of them, as well as how to manage them:

Upfront investment cost: Automated packing machines are expensive. They need upfront costs for equipment, installation, and integration. This can pose a challenge for small startups or growing businesses. However, as time goes on, the initial capital investment is often offset through labor savings, higher efficiency, and reduced product loss.

Need for operator training: Automated machines are equipped with designs and features that require experienced personnel to operate, monitor, and maintain them. If there are no trained operators, the machine may experience a fault or inconsistent performance, and this will lead to downtime. Work with suppliers who offer training and technical guidance to help workers operate easily.

Product variability: Agricultural products differ in size, texture, shape, and fragility, which can affect automation if machines are not properly installed and configured. Select machines that have flexible systems, i.e., can handle products with different characteristics. This will enable you have a smooth workflow, increased efficiency, and productivity.

Integration with existing workflows: Transitioning from manual to automated workflows can be overwhelming. Integrating new automation into the current agricultural processes needs careful planning. Otherwise, you could encounter disruptions that would negatively affect workflow. Work with suppliers with reliable support to help ease the transition.

Packing automation offers several benefits, from efficiency to reduced labor and agility. However, by considering the key factors and managing challenges effectively, you’ll be able to boost productivity.

Are you looking for automated packing machines for your projects? Contact Hualian Machinery for more information.

Automatic packing machines are environmentally friendly because they reduce material waste, and they are energy-efficient. They also use sustainable materials like paper, leading to a smaller carbon footprint. As a result, they improve product protection and minimize spoilage.

Packing automation minimizes human error and injuries that often come from manual handling. It also boosts consistency and enhances safety through precise weighing control, high-speed operation, and reduced product recalls.

Packing automation machines have smart features that enhance efficiency and productivity. Some of these features include robotics, artificial intelligence, integrated sensors, and cameras. These features enhance quality control by inspecting the product for defects. Thus, they ensure regulatory compliance.

Automated packing machines are used in the food industry to boost speed, consistency, and safety by reducing manual intervention, errors, and waste. Furthermore, it lowers labor costs and ensures precise packaging, leading to enhanced product quality and adherence to safety standards.