Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

Table of Content

1. What is an Open-Mouth Bagging Machine

2. Types of Open-Mouth Bagging Machines

3. Key Factors to Consider When Selecting an Open-Mouth Bagging Machine

4. Open-Mouth Bagging Machine Applications

5. Why Choose the Right Open-Mouth Bagging Machine

Are you looking for an efficient open-mouth bagging machine for your business? Understandably, you’ll face the challenge of making the right choice, especially with lots of options out there. However, selecting the right one can significantly impact production efficiency. Because we have you in mind, we present this detailed guide to help you make a choice.

An open-mouth bagging machine, or bag mouth opening machine, is a type of automated bagging machine that has an open mouth on it. In other words, it is used to fill and seal pre-made bags that are open on one end.

These machines are automated to hold the bags open, fill them with products, and seal them with a variety of sealing methods. The bags are often made of paper, plastic, or polypropylene and are used to bag free-flowing materials.

The main components of this machine include:

Feeding hopper

Bag storage platform:

Bag separation and feeding mechanism

Upper bagging mechanism

Opening bag mechanism

Vibrating bag mechanism

Frame

Electrical control cabinet

Exhaust and bag-holding mechanism

This is a type of bagging machine that uses a single weighing mechanism to measure and fill a bag with a consistent amount of products. That is, the product is fed into a hopper, and a single weighing head dispenses the exact amount into each bag.

It is suitable for a small to medium-scale production. It is also ideal for a 25kg bagging machine and can efficiently bag free-flowing products. For instance, you can bag granular and powdered materials with accuracy and flexibility.

As the name suggests, the multi-head weighing bagging machine has multiple inlets arranged in a radial or linear format. The product is distributed across several weighing heads, and a computer calculates the optimal combination to reach the desired bag weight quickly and accurately.

This helps you bag products of larger sizes and achieve higher packaging speed. It is most useful in bagging granular materials, snacks, animal feed, and plastic pellets. Furthermore, it supports automated bagging systems for products where precision is required.

This bagging machine is used in cases where rapid throughput is required, as in massive production. This machine can fill and seal hundreds, and even thousands, of bags (typically 1000 packages per hour).

This bag placer machine has advanced automation that handles bag placement, filling, weighing, and sealing in a continuous, high-volume process. It is mainly used for bagging cement, fertilizer, grain, animal feed, and pet food.

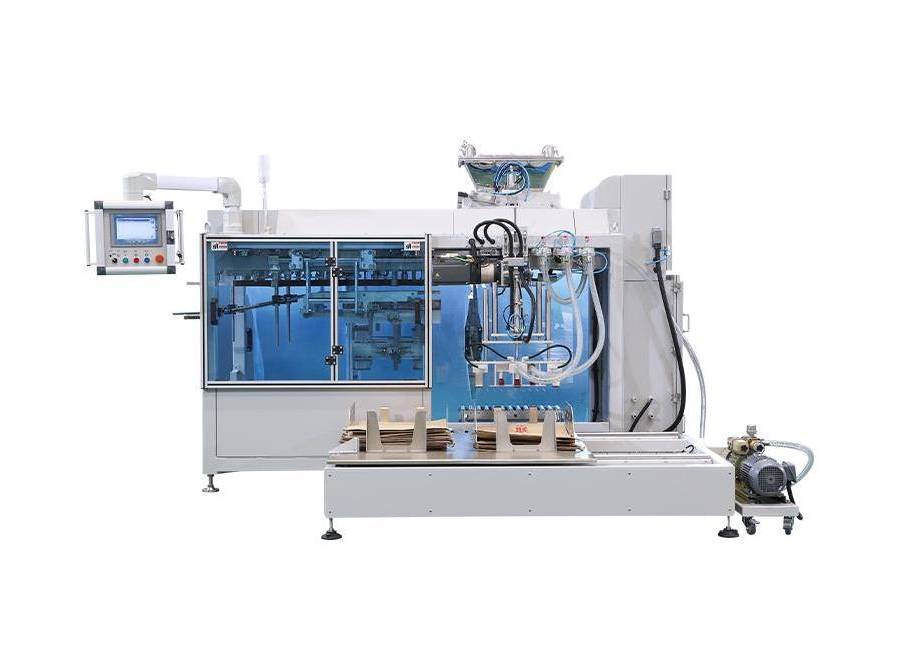

Our Automatic Open Mouth Bag Placer is a fully automatic high-speed bag placer used for packaging 10kg - 50kg of powdered materials. With a combination of a bag placer and a bag closing system, it can handle bags of different specifications for a faster production line. A flexible machine like this is what you need to keep your business running.

This machine is mainly used for packaging powdery materials. To prevent dust from flying, a bottom-filling method has been adopted. The bag is placed over a filling tube, and the product is pushed upward (that is, from bottom up) into the bag, reducing air entrapment and dust.

Additionally, we can add a dust explosion prevention system to this bagging machine. It works effectively with flour packaging machines for products that require gentle handling.

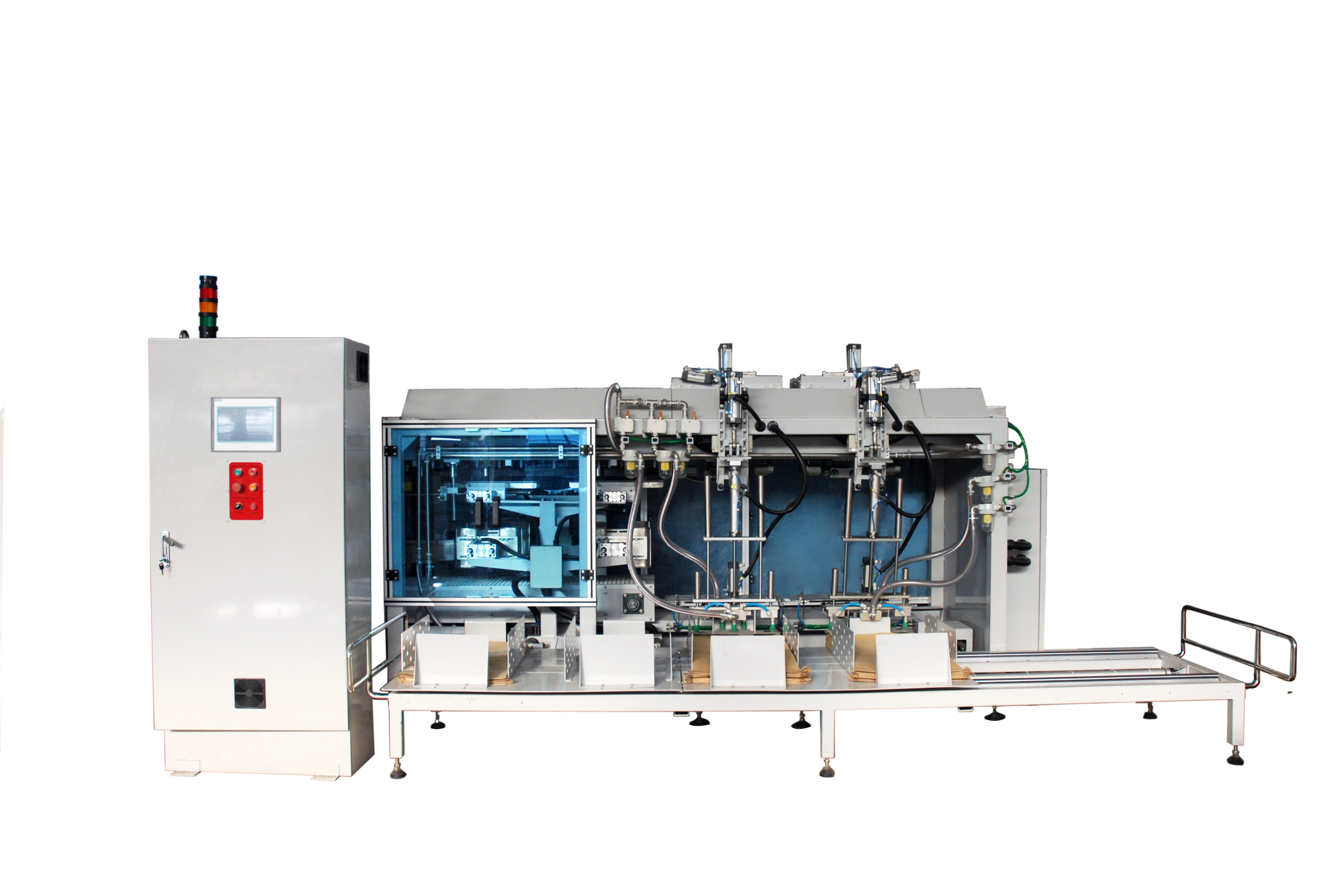

This bagging machine performs multiple functions, including feeding, packaging, sealing, and transportation. Since it has an open-mouth bagging machine, a bag closing system, and a conveyor belt, it can perform multiple capabilities in a unified, centralized system.

The machine often uses robotic handling to handle a series of operations, which may even include labeling, metal detection, and palletizing. Thus, it is applicable in multi-product lines and large industrial operations. You can use it to bag food, chemicals, and building materials.

The product texture should determine the kind of bagging machine to choose. To improve filling accuracy, some products may require vacuum or deaeration systems. Others may need a different feeding mechanism to improve flowability and prevent spillage.

For example, if your product is free-flowing, powdery, dusty, or granular, you should get a machine with enclosed systems to reduce dust. If your product is dense, it may need deaeration by gravity-fed machines to prevent air pockets. It is recommended that you choose a machine that can bag a variety of products for optimal production.

The shape and size of your bag will determine the kind of open-mouth bagging machine to use. Some bags are simple to use, others are fragile and need gentle handling. Still, others require complex handling.

Keep in mind, too, that some machines work effectively with smaller bag sizes. Others are flexible to handle different bag sizes and weight ranges (5kg, 25kg, 50kg, etc). Some advanced machines offer adjustable features and multiple sealing methods to provide versatility. So, you may want to opt for machines that can swap sealers when necessary, not those with a single sealer mechanism.

You should also check if the machine is compatible with the bag material. Can it handle a paper bag, a plastic bag, or a polypropylene bag?

Determine the required bag production per minute/hour. Some machines operate at high speed and can handle dozens of bags per minute. They are ideal in situations where speed is highly needed and can boost productivity. So, before choosing a machine, determine your production speed based on your output needs.

Additionally, choose a machine that can handle future needs in the event you want to expand your scope. If your machine can handle more than it can do at present, that’s to your advantage.

Decide beforehand on the level of automation you need for production. Semi-automatic machines require a significant amount of manual intervention. You’ll need to incur labor for bag placement, which may increase labor costs.

A fully automatic bagging machine helps you automate everything in your production line. From bag placement to filling, weighing, sealing, and more. This machine increases speed and production efficiency, minimizing human error and fatigue. While it incurs a huge cost at first, it pays off in the long run.

You should also find out if the machine can be integrated into existing equipment for a smooth, automatic bagging system.

Accuracy has a direct impact on productivity, and a slight deviation might cost you a great deal. Therefore, you should check whether the machine can accurately weigh, fill, and seal bags to prevent errors. Find out the type of weighing systems that are employed.

Machines with net weighers are considered faster and more accurate. Those with metal detectors can further ensure quality control to ensure that it is giving you the best output continuously.

This is undeniably one of the foremost things to consider before choosing an open-mouth bagger. If you are seeking a machine that is pocket-friendly, you can go for a semi-automatic machine that offers a reasonable level of automation. However, a bigger budget gives you a big win, full automation with sophisticated features.

For the initial investment, you should factor in the cost of the machine, installation, and any other accessories. Additionally, you should consider operational and maintenance costs, which may include energy consumption and the cost of consumables.

A fully automatic machine will incur higher operational and maintenance costs. But it will yield a faster return on investment (ROI).

Before you choose a machine, determine your factory layout and floor space. Some machines are compact and can be used for smaller facilities. Others offer greater flexibility and convenience. So, evaluate your space requirements and machine dimensions to ensure you’re on track.

Is the machine easy to operate? How long does it take to maintain the machine? How often do you need to maintain it? Machines with a user-friendly interface can be operated by beginners, so much training or expertise may not be needed. This can have a huge impact on productivity.

Evaluate the availability of spare parts. If they are readily available, this can minimize downtime and boost production. Look for machines that are easy to maintain, disassemble, and easily accessible.

Look for machines built with durable materials for corrosion resistance and continuous use. For instance, machines built with stainless steel are ideal for food hygiene, plastic are ideal for corrosive chemicals. Machines should withstand dust, vibration, and continuous operation.

It is recommended that an open-mouth bagging machine have enclosed filling heads for food, flour, or chemical packaging. If the machine is equipped with remote diagnostics, it can predict maintenance and reduce downtime.

Look for machines with emergency stop buttons, guarding and enclosures, and easy-access maintenance panels. These adequate measures not only protect the machine but also the operators as well. As a result, accidents can be minimized.

Look for established open-mouth bagging machine manufacturers with experience. With a proven record of excellence, they should be able to provide:

Installation and maintenance

Spare parts, if needed

Training for you and your employees for safe operation

Ongoing support after sales

This is where Hualian Machinery comes in. With our years of experience, we offer preventive maintenance programs and technical support to keep your machine running when you need it the most.

Dust control is a crucial concept in the chemical industry to guarantee quality products. Powder forms such as soda ash, flame retardants, leavening agents, and other chemical raw materials require the use of an open-mouth bagging machine to handle them. Thus, they can be packaged in open bags, polyethylene (PE) lined bags, paper plastic composite bags, etc.

Granular materials like plastic particles and sand have high fluidity and require accuracy and precision in weighing. Thus, an open mouth bag packing machine bags these products in polyethylene (PE), polypropylene (PP), woven, and Polyamide (PA) bag materials.

The agricultural and food industry is one of the largest consumers of open-mouth bag filling machines. For granular products like rice, wheat, corn, and other grains, this machine offers hygienic construction for food-grade applications.

The machine also bags bulk products like dried fruits, nuts, and specialty flours. You can also bag sideline products like salt, sugar, and spices to reduce overfill and product loss.

In the wholesale industry, woven bags are often used to save costs. In the retail industry, some high-end grains and agricultural food packaging, paper-plastic composite bags, aluminum foil film bags, etc., are mostly used.

Flour packaging machines bag powdered products like flour, milk powder, etc. To avoid moisture, polyethylene (PE), polypropylene (PP), and paper-plastic composite bags are mostly used. The open-mouth bagging machine can handle different bag types and weights, meeting diverse export and wholesale packaging needs typical of agriculture.

The animal feed industry relies on open-mouth bagging machines for bagging mostly granular products like cat food, dog food, fish food, and other feeds. Machines with high throughput are usually needed to bag livestock supplements and poultry feeds.

The weight of feed packaging is usually around 10-25kg. Most pet foods, to improve the appearance of the packaging, often use polyethylene (PE), polypropylene (PP) bags with colored printing on the surface. Machines with durable components are also required to handle abrasive feed materials.

Feed mills, dealing with both pellets and powders, utilize machines equipped with dust containment systems to maintain cleanliness. Consistent and accurate filling is required to ensure the product retains nutritional value.

The compound fertilizer industry uses woven bags, paper-plastic composite bags, etc. Machines equipped with gravity or vibration feeding devices handle blended or granulated fertilizers. Those with dust removal and spiral feeding devices handle powdered materials.

Machines built with durable materials are often used to handle the corrosive properties of fertilizers and soil conditioners. Different feeding equipment is used to adapt to different materials. The rear-end sealing system (bag closing system) can be selected according to the different material packaging bags.

Machines with large-format bag compatibility can handle fertilizer bagging up to 50kg. They also provide fast changeover for different fertilizer grades.

Selecting the most suitable open-mouth bagging machine can bring the following added benefits:

Opting for a machine with high-speed operation and a fully automated system speeds up production. Because they can handle bags of different sizes and materials, you get faster cycle times and reduced downtimes. This is crucial for your business, especially if time sensitivity is prized.

Overfill, underfill, and spillage can eat up your profit. By choosing the right machine, you can induce controlled filling. In the long run, this can increase production speed and lower packaging costs.

Choosing machines equipped with safety measures means you care, not just for your life, but the lives of your employees. Those with dust control systems, shields, and others reduce the occurrence of accidents. This promotes a safe working environment - a must for reduced liability.

Product presentation matters to consumers, and open-mouth bagging machines can help push appealing products to them. With automated sealing methods, machines can make bags attractive, protecting the product from the inside and enhancing its look on the outside.

As your business expands, you’d want a machine that can meet future needs without the need to purchase a separate one. Many models allow you to upgrade their existing systems to cater to future demands. This adds a competitive advantage, making your business stand head and shoulders above others.

Choosing the right open-mouth bagging machine for your business requires careful evaluation. Your product type, budget, and future goals are some of the things you need to factor in to invest in the best.

Work with trusted bagging machine manufacturers like Hualian Machinery for quality and customer support.

Open-mouth bagging machines fill bags with an open top. The bag is placed under a fill spout, filled with the product, and then typically conveyed to a sealing station where it is sewn, heat-sealed, or glued closed.

A valve bagging machine uses a valve to automatically close a bag after filling. The valve design ensures a faster filling process and controls dust.

Industries like agriculture, food, and the chemical industry use open-mouth bag fillers. They handle bulky and dry materials like sugar, salt, seeds, animal feeds, etc.

Machines commonly use heat sealing. This involves applying controlled heat and pressure to plastic or thermoplastic materials, causing them to melt and fuse together. However, others use ultrasonic sealing, sewing, or gluing. The sealing technique depends on the bag material and application requirements.

Prices may differ based on the level of automation, material, and supplier. You can find one within the range of $20,000 - $60,000. Additionally, these machines can be customized according to different functional requirements and equipment needs.